Fish Ball Machine

Fish Ball Machine

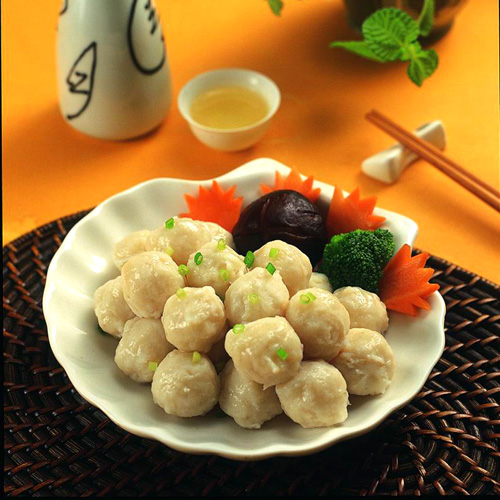

Fish Ball Making Machine

With certain rotating speed, the blade feeds paste to the cavity of forming gear continuously. Meanwhile, paste revolves along with the gear. With cup-shaped mould controlling the size of the ball, the reamer will make near-spherical balls regularly with even distribution of weight. According to the viscosity of the paste, the frequency converter can be modestly adjusted to regulate the speed of the machine and thus perfects the shape of ball.

Flow Chart

Type 1: Meat cutting machine-- Meat Grinding machine—Meat beating machine—meat ball forming machine—Shape forming water tank--- Boiling tank---Cooling tank-Freezing-Packing

Type2: Meat cutting machine-Meat grinding machine-Meat mixing machine- Meat ball forming machine-First frying machine for forming shape- Second frying -Cooling tank-Freezing-- Packing

Technical Parameters of Fish Ball Making Machine

Model | YW500A(with inverter) | YW500 (without inverter) |

Power | 1.5KW | 1.5KW |

Capacity | 500pcs/min | 500pcs/min |

Weighty | 200KG | 190KG |

Material | All stinless steel | All stinless steel |

Export Port | FOB Xiamen, China | FOB Xiamen, China |

Overall Dimension | 1000*400*1790(mm)

| 1000*400*1790(mm)

|

Notes

1. Application voltage environment should be given when making order, so as to choose the proper electric motor.

2. The warranty time for our fish ball making machine is 1 year, excluding belt. We offer charged maintenance services when warranty time is over.

3. Always wearing noise reduction earplug and hygienic uniform. Non-trained personnel are forbidden for machine operation.